Fastener Inspection Overview

Uncover huge time savings and improved accuracy for your fastener inspections!

Accurex Fastener Measurement Tool (FMT) inspects aerospace fasteners in seconds to ensure both structural and aero smoothness requirements are met for both flat and contoured surfaces.

FMT is 3 solutions in one

- Countersink inspection

- Fastener flushness measurement

- Defect assessment

With extremely fast and reliable fastener inspection, aircraft manufacturers can achieve rate and quality goals, while quickly detecting and remedying any process errors.

FMT is widely used for fastener inspection on the F-35 fighter aircraft and was recognized by USAF as a rate enabler. FMT is now available for broader application on commercial, business, military and other aircraft.

Capabilities

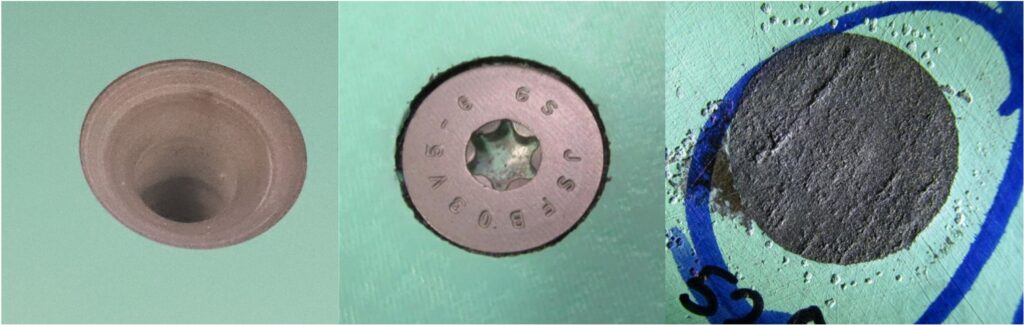

Countersink inspection

Accurex Fastener Measurement Tool (FMT) accurately measures important characteristics of countersunk holes and precisely predicts final flushness when a fastener is installed. FMT can report OML diameter, countersink angle and axis angle.

Routine countersink inspection with FMT enables manufacturers to quickly validate countersink operations.

If countersink errors are detected, the manufacturer can address BEFORE incurring the time and expense of installing fasteners.

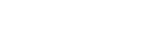

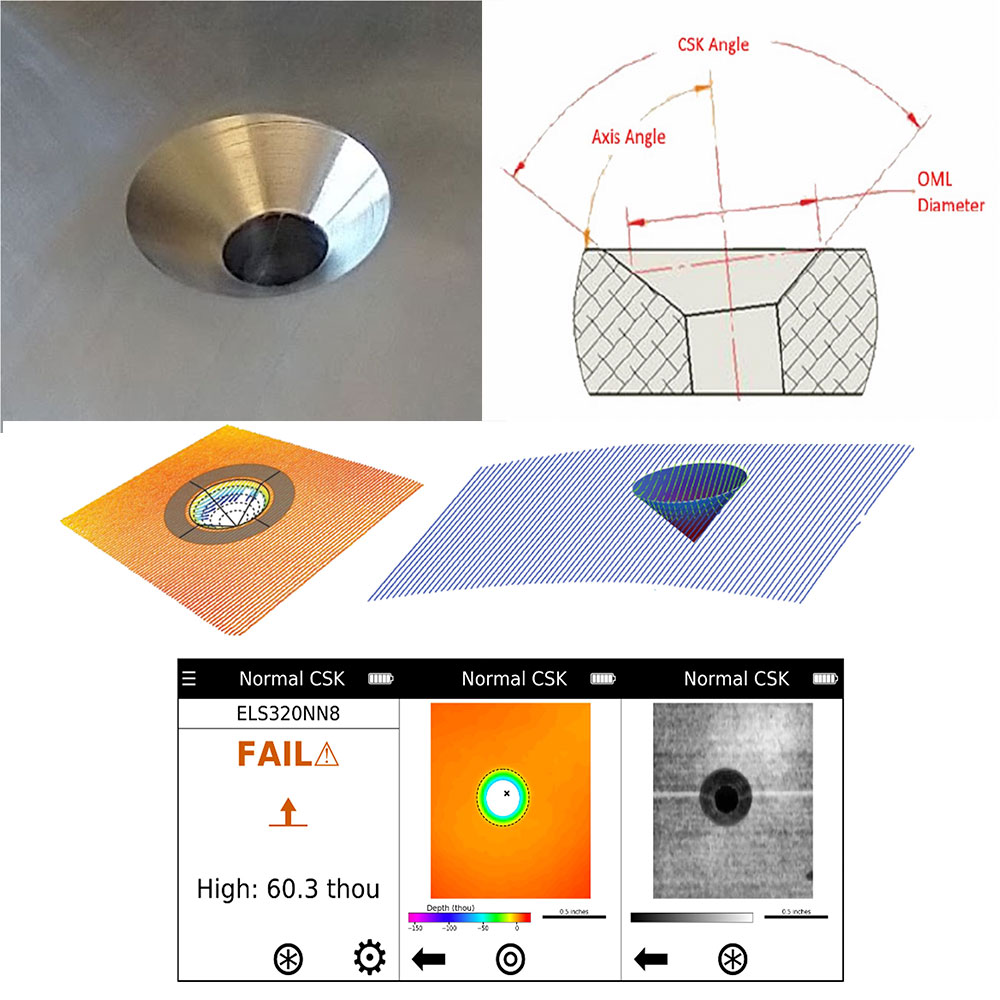

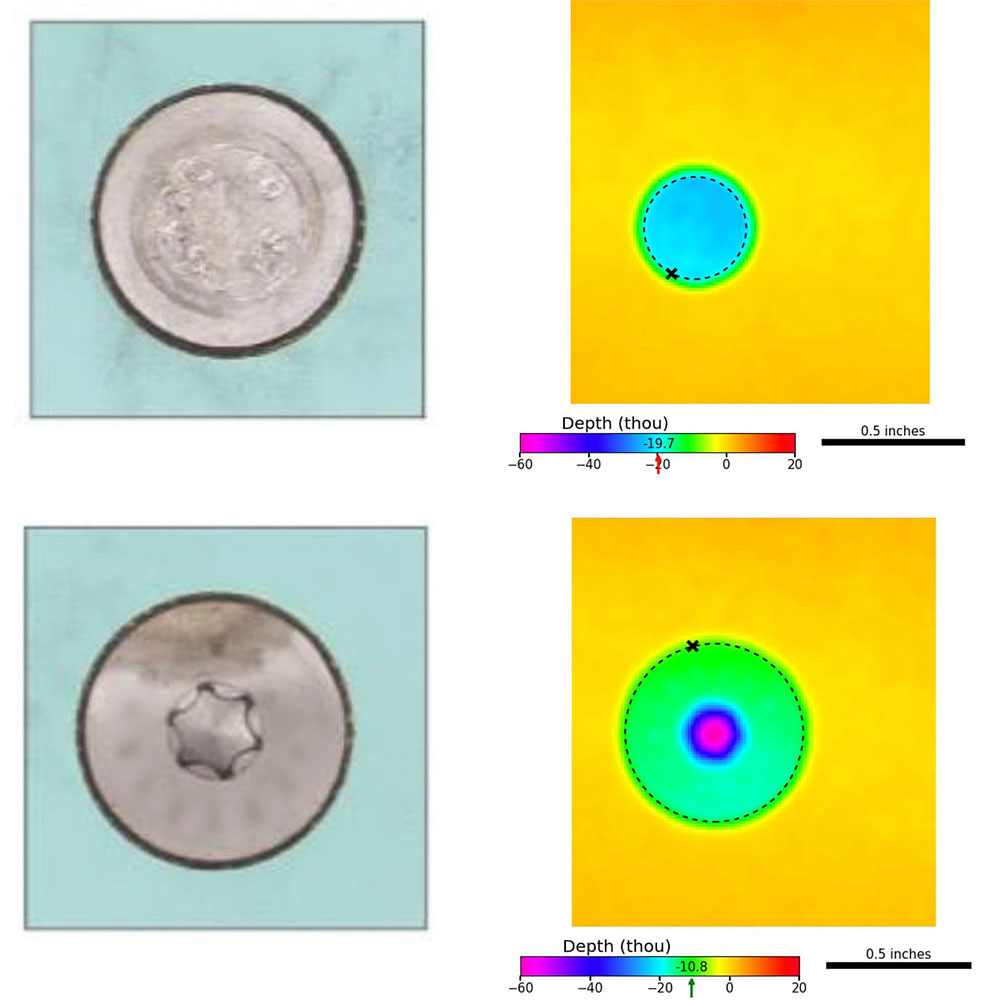

Flushness measurement for unfilled fasteners

Accurex Fastener Measurement Tool (FMT) instantly assesses flushness of installed fasteners. FMT can report high point and low point of the fastener compared with surrounding surface with accuracy to 0.0003”

Manufacturers save hours on fastener inspections since FMT is up to 10x faster than traditional flushness protrusion gauges. Faster inspection → better process monitoring → detect problems sooner = eliminate cost and headaches.

FMT uses full 3D point cloud data to evaluate installed flushness of different fastener types.

Defect assessment

Accurex Fastener Measurement Tool (FMT) quickly determines precise depth of scratches, pits, dings, dents and nicks on material surfaces or filled fasteners

FMT uses a patch of full 3D point cloud data to characterize defects in seconds and extract the deepest and highest points relative to the surrounding surface regardless of whether it is flat or curved.

With FMT, manufacturers determine instantly on the shop floor if a surface defect like scratch or pit requires rework or repair

How It Works

FMT is a handheld laser scanner developed specifically for aerospace fastener inspection on the shop floor. FMT instantly captures a dense 3D point cloud with patch size of 1.5” x 2” (38x50mm). Its onboard processer analyzes the full 3D data using specially developed algorithms to provide complete and reliable characterization of fasteners and countersink dimensions in a couple seconds.

The built-in touch screen display shows immediate pass/fail results to the operator with option for more detail as needed and upload of results for reporting and quality recordkeeping.

Discover Accurex Fastener Measurement Tool (FMT)

Download Our F-35 Case Study