The ability to accurately measure and inspect bent tubes with rectangular cross-sections is essential for manufacturers aiming to maintain high standards of quality and efficiency. Traditional methods for checking tube geometry can often be cumbersome and time-consuming, but with advancements in optical measurement technologies, the process has become significantly easier and more effective. Here’s how to ensure precision in measuring and inspecting rectangular tubes.

Understanding the Importance of Accurate Measurement

Rectangular tubes are commonly used in products across various industries including automotive, furniture, recreational vehicles, heavy equipment and others. Tubes are often formed using CNC benders to specified shapes required to perform their function.. Ensuring that these tubes meet specific dimensional tolerances is crucial for the overall integrity of the final product. Accurate measurements can streamline the setup process for benders and ensure that components fit together as intended.

Traditional Measurement Challenges

Traditional measurement techniques, such as using Coordinate Measuring Machines (CMM) or hard gauges, can pose challenges. CMM’s require extensive programming and measuring time while gauges are expensive, costly to store, require effort to maintain, and provide no guidance towardsa remedy when a part fails to fit in a gauge.

The Advantages of Optical Measurement Technologies

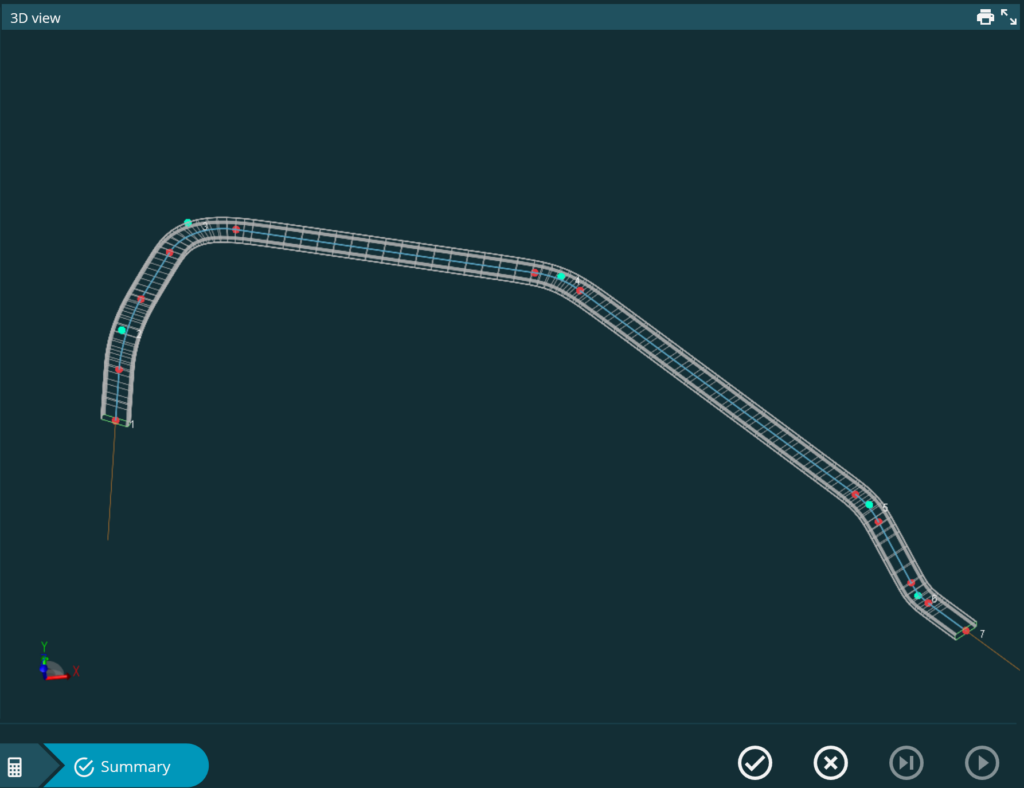

Optical measurement systems like TUBEINSPECT and Hexagon Absolute Arm provide a revolutionary solution for accurately measuring rectangular tubes. Here are some of the benefits:

1. Non-Contact Measurement

Optical systems eliminate the need for physical contact with the tube, reducing the risk of damage or deformation to part or probe during inspection. This non-contact approach allows for quick and reliable measurements without the complexities involved in traditional methods.

2. Speed and Efficiency

With TUBEINSPECT, measurements can be completed in seconds. This rapid assessment not only enhances productivity but also allows for immediate feedback and adjustments during the manufacturing process.

3. No Fixturing Required

TUBEINSPECT is designed to measure rectangular tubes without requiring fixtures or holding devices. This flexibility significantly streamlines the inspection process, allowing operators to focus on production rather than setup.

4. Integration with CNC Bending Machines

One of the standout features of TUBEINSPECT is its capability to automatically correct bending parameters based on measured data. If any adjustments are needed, corrections can be sent directly to CNC bending machines, minimizing downtime and increasing efficiency.

Best Practices for Measuring Rectangular Tubes

To achieve accurate measurements and inspections of rectangular tubes, consider the following best practices:

- Use High-Quality Optical Measurement Systems: Investing in advanced technology like TUBEINSPECT can drastically improve measurement accuracy and speed.

- Establish Relevant Inspection Criteria: Ensure that the inspection plans defined for the tube evaluate based on criteria that truly indicate whether it will fit for its intended purpose..

- Train Operators: Although modern systems are user-friendly, proper training ensures that operators can maximize the capabilities of the technology.

- Implement a Quality Control Process: Incorporate regular checks during production to identify any deviations early and address them promptly.

Contact Accurex For Accurate Tube Measurement

Accurate Measurement’s solutions for inspection of bent rectangular tubes are crucial for maintaining quality in manufacturing. Accurex’s TUBEINSPECT technology transforms this process by leveraging advanced optical measurement solutions, enhancing productivity while ensuring high-quality standards.

With TUBEINSPECT, manufacturers can achieve faster setups and reliable results, positioning themselves for success in a competitive market. To discover how Accurex can elevate your tube bending measurement processes, contact us to discuss your specific application needs!