In manufacturing and quality control for precision machined components, the accurate measurement of radius is vital to ensuring that parts meet design specifications and function as intended. The correct measurement of radius can influence everything from part fit to structural integrity. This guide will walk you through the importance of radius measurement and the best tools available for precise radius measurement.

Understanding Radius Measurement in Manufacturing

A radius is the distance from the center of a curve or circle to its edge and is a fundamental geometric parameter in many manufactured parts. Radii appear in fillets, bends, grooves, and rounded edges, and their accuracy affects how parts assemble, wear, and perform under stress.

In sectors such as aerospace, automotive, energy, and heavy machinery, radius measurement is critical for:

- Ensuring proper mating between components

- Avoiding stress concentrations that could lead to premature failure

- Maintaining aesthetic and ergonomic requirements

- Meeting safety and regulatory standards

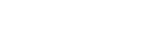

Incorrect or inconsistent radii may cause assembly issues, product recalls, or even safety hazards. Product drawings specify controls on machined radii. In addition to standard Radius control shown above, there are related controls specifying Controlled Radius, Round Edge, and others. Hence, precise radius measurement is a non-negotiable part of quality assurance.

Tools for Measuring Radii

Different tools suit different manufacturing environments and precision requirements. Here are some widely used options:

1. Radius Gauges

Radius gauges are simple, handheld tools featuring a series of fixed-radius profiles. Operators visually compare the gauge profiles with the part radius to find the closest match.

- Pros: Inexpensive, portable, easy to use

- Cons: Limited precision, subjective results, no digital data outputl

2. Optical Comparators

Optical comparators project a magnified shadow of the part (or shadow of a rubber mold from the part) onto a screen where radii can be measured against overlays or digital readouts.

- Pros: Good accuracy, visual confirmation

- Cons: Requires setup time and trained operators

3. Coordinate Measuring Machines (CMM)

CMMs use touch probes or lasers to capture detailed 3D data points along a curved surface for radius calculation.

- Pros: High precision, comprehensive data

- Cons: Expensive, slow for high-volume inspections, not suitable for very small radii

4. Laser Profile Optical Measurement Systems

Advanced optical systems use lasers or structured light to scan parts quickly and accurately without touching them. These systems generate a digital reproduction of the surface profile from which radii are extracted.

- Pros: Fast, highly accurate, no physical contact or fixturing needed

- Cons: Initial investment cost;

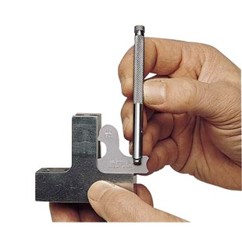

Boost Your Quality Assurance with GapGun Pro2 from Accurex

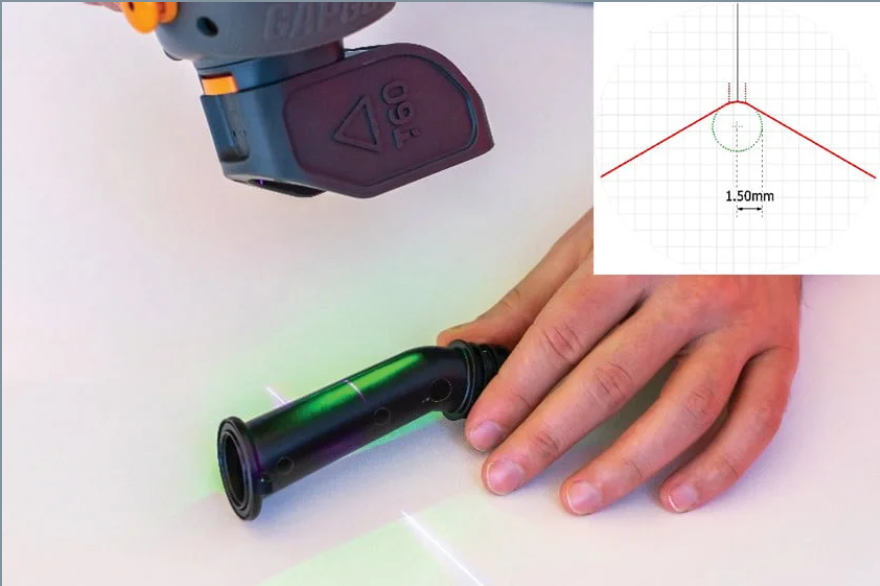

Accurex understands that precision radius measurement is key to delivering quality products. That’s why we offer the GapGun Pro2, a state-of-the-art laser profile measurement tool ideal for inspecting radii as well as chamfers and break edges on precision machined components.

The GapGun Pro2 provides:

- Quick and accurate radius measurement without contact

- Easy shop floor measurement with real-time digital feedback suitable

- Portability combined with rugged design for demanding industrial environments

- Ability to automate measurement when frequency of inspection is high

Elevate your quality control processes with Accurex’s GapGun Pro2 — contact us today to learn how this tool can streamline your radius inspections and improve your manufacturing outcomes.