TubeInspect Applications

Supercharge your tube and wire bending operation with optical measurement technologies. Measure bent tubes in seconds and boost manufacturing productivity.

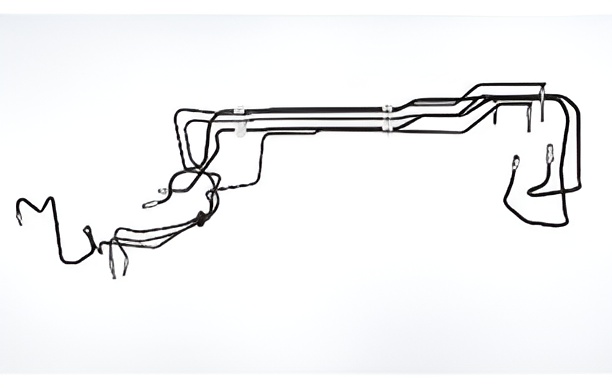

Brake Lines

Automotive brake lines are notoriously difficult to inspect and in fact it was that measurement application initially drove the invention of the TubeInspect system. Brakelines often have 30-50 bends in small diameter tubing that will flex under its own weight. Despite these challenges, TubeInspect can measure and provide corrections to slash the setup times for manufacturers of automotive brake lines.

Exhaust

Exhaust tubes are larger diameter tubes that are sometimes deformed during bending with ovality and wrinkles. They often have complex shapes with short straights, flared ends and bevel cuts. BendingStudio solutions can handle all of these for parts straight off the bender as well as ones that have been trimmed and need to inspect bevel angle and position of welded-on hangers.

Hydraulic

Hydraulic lines come on many shapes and sizes. They usually end up with straight, L or T fittings on the ends and often have one or more fittings in the middle. The fittings may be welded or brazed after bending, or they may already be there when the tubes are bent. Regardless of the process, BendingStudio solutions can measure with and without fittings for the purpose of both bender setup correction and final inspection of tubular assemblies.

Hair Pin

The hairpin wires that are critical for efficient and powerful stators in electric vehicles have complex 3D shapes that need to be very precise. The Hairpin Inspection system, based on BendingStudio, can perform full 3D inspection of these parts in a few seconds.

HVAC

HVAC systems for residential, commercial and specialty applications contain numerous tubes for refrigerant transport, heat exchangers, etc. These are usually copper or aluminum tubes, both of which can be challenging to bend consistently. These tubes have all sorts of bends, may have end expansions or contractions and often have one or more holes along the tube. BendingStudio solutions can check bending shape to calculate bender corrections, measure the length of end expansions and evaluate the position and orientation of the holes that have been placed into the tube.

Fuel Tubes

Fuel tubes run the range from a couple inches up to a couple meters, depending on the vehicle on which they will be mounted. They use strong material, often have shapes with lots of bends and little straight sections and usually end forming or fittings. Despite these challenges, BendingStudio solutions can measure such tubes quickly and consistently.

Structural

Tubes are used as basis for all manner of structural elements – furniture, frames of specialty vehicles, door rings for offroad vehicles, sunshades and tow bars for boats, grill guards for trucks – the list goes on and on. Structural tubing may be round, square, rectangular or oval and is bent into shapes from simple 90 bends to sweeping bends that loop around and back where the end almost touches the start. These tubes often have coped or beveled ends and laser-cut holes. BendingStudio can measure the bending profile for all and on round tubes can inspect the bevel angle hole positions using CAD Adapter functionality.

Automotive Heater/AC lines

Tubes for automotive climate controls systems range from around 300mm to the full length of a truck at 3m or more with lots of shallow bends. Heater lines usually have beaded ends while the AC refrigerant lines have charge ports, welded-on brackets, hose sockets and peanut fittings. Even with all this complexity, BengingStudio can inspect the tube component itself as well as the assembly with fittings, brackets and ports. The refrigerant lines are usually assembled into a final line with a combination of rigid tube and rubber hose. TubeInspect system can even inspect the tube-hose combination when it needs to be inspected.

EV Busbars

Busbars for electric vehicles come in all shapes and sizes, from short connections inside battery pack to long connections inside the body. Some are round, some are rectangular. Some busbars have clean cut ends, others have connection holes punched while others have some form of connector. BendingStudio solutions can handle each of these challenges for round busbars and most for rectangular. Learn more about busbar inspection here:

Variable radius/Freeform

Though most tubes are produced with traditional mandrel bending with fixed bend radius, there are other bending methods which enable manufacturers to produce tubes with variable radii and what are called freeform parts, meaning the centerline is a spline curve rather than a combination of straight lines and fixed radius bends. Such parts are used in a variety of applications including architecture and in-home mobility systems. BendingStudio has the ability to measure such parts and can even apply corrections with some freeform benders.

Automotive Suspension

Stabilizer and sway bars for automobile suspensions use formed rods or heavy wall tube to provide rigidity and control of vehicle dynamics. These materials are tough to bend and usually have ends that have been flattened with holes for attachment to the vehicle. BendingStudio can measure the bend profile for bending correction as well as the location of the end holes for final inspection using its drillhole capability.