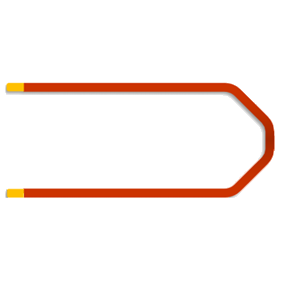

3D Hairpin Inspect

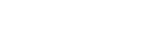

3D Hairpin Inspect is a dedicated solution for the high-speed measurement in the production environment of stator hairpins for electric vehicle motors. The system supports the full process, including all steps to setup a hairpin production machine.

Instant Shop Floor Inspection to Support Stator Hairpin Production

Accuracy of the many conductors is important in the production of electric vehicles. 3D Hairpin Inspect is a solution developed specifically to address the need for accurate measurement of stator hairpins with their rectangular cross-sections, tapered end and complex 3D shapes

Manufacturers of motors for electric vehicles face many challenges when producing stator hairpins:

- Material that requires careful handling

- High number of part variants

- Varying material properties

- Demanding surface characteristics

- Tight tolerances in stator slot / crown assembly

- High volume production

3D Hairpin Inspect Addresses these with 3D Optical Inspection Technology that provides:

- Fast & accurate inspection on shop floor

- Ability to inspect all critical dimensions

- Easy – learn in 5 minutes

- Streamlined workflow to set up new hairpins

- Inspect parts at all stages of product: 1D, 2D and 3D shapes

Single Solution Measures Part at All Stages of Production

1

Wire Cut to Length

2

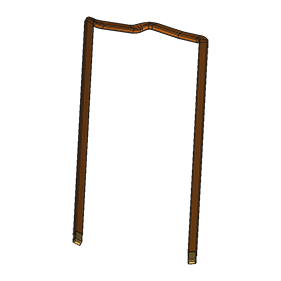

Formed with 2D Profile

3

Stamped to 3D Shape